1. After analyzing the requirements of the customer, we offer a customer-focused design depending on the application type and quantity.

2. We keep the customers satisfied through top-quality fabrication, realized to the international standards.

3. We closely monitor advances in the-state-of-the-art and quickly adapt the same to our products. With a single button and a single operator approach, we made operations very comfortable.

4. Under no circumstances we compromise product’s standards for the sake of sustainable quality.

5. The machine is ergonomic and quick and practical to transport, set up and deploy.

6. Through high and quick ROI (return-on-investment), its investment and operating costs are minimized.

7. Plant’s safety and security are assured without compromise in conformity with international operating rules.

8. Product quality is maintained for the sake of sustainability.

9. Through modern infrastructure instruments the data is processed correctly and accurately reported and stored.

10. The system is always under control thanks to real time data transfer and remote monitoring capability.

11. We provide after-sale services at any point in the world to the same standards and without interruption.

12. The training is provided to the top management, quality control and maintenance personnel and operators, depending on their needs.

The perfect combination of distribution of droplets between emulsion phases and optimum droplet sizes, applications of this plant make a difference and increase its popularity.

Measurement accuracy of the flow meters used in dosing, has a direct impact on the resultant product quality.

Thanks to automatic PID control a stable/steady production is assured without need for an input by an operator.

Production capacity is always automatically controlled.

Temperature and pressure safety values are double secured through mechanical and electronic measurements.

Thanks to being ready for a static mixer, it is possible to dope into bitumen, solution and emulsion lines, thereby diversifying the emulsions.

An electric heating system has been employed for energy economy and safety.

The plant is operated by a single operator.

The product quality of the plant is assured through a bench type laboratory mill, as indicated in the model.

| MODELS | |||||||

| TECHNICAL SPEIFICATIONS | EMTES 3 | EMTES 5 | EMTES 10 | EMTES 15 | EMTES 20 | CUTBACK30 | LAB TES1 |

| CAPACITY ( T/h) | 3 | 5 | 10 | 15 | 20 | 30 | 1 |

| TYPE OF PRODUCTION | |||||||

| BATCH PRODUCTION | ✓ | ✓ | ✓ | ✓ | ✓ | CUTBACK PROD. | ✓ |

| CONTINUOUS PRODUCTION | ✓ | ✓ | X | X | X | X | |

| PORTABILITY | 20’&40’DC KONT | 20’ KONT. | WxLxH

2,3×7,5×2,4 |

40’DC KONT | 40’DC KONT | 20’&40’OT KONT | MOBILE |

| NUMBER OF SOLUTION TANKS | 1&2 | 1 | 1 | 2 | 2 | X | 1 |

| SOLUTION DOSING | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER | ROTOMETER | MAGNETIC FLOWMETER |

| BITUMEN DOSING | MASS FLOWMETER | MASS FLOWMETER | MASS FLOWMETER | MASS FLOWMETER | MASS FLOWMETER | MASS FLOWMETER | MASS FLOWMETER |

| EMULSION COLLAIDAL MILL | |||||||

| TYPE | GAP ADJUSTABLE & INVERTER | GAP ADJUSTABLE & INVERTER | GAP ADJUSTABLE & INVERTER | GAP ADJUSTABLE & INVERTER | GAP ADJUSTABLE & INVERTER | STATIC MIXER | GAP ADJUSTABLE & INVERTER |

| DROP DIAMETER (mm) | 0,003 | 0,003 | 0,003 | 0,003 | 0,003 | X | 0,003 |

| SOLVENT DOSING | GEAR FLOWMETER | GEAR FLOWMETER | GEAR FLOWMETER | GEAR FLOWMETER | GEAR FLOWMETER | X | X |

| EMULGATOR DOSING | |||||||

| ACID DOSING | LOADCELL | LOADCELL | LOADCELL | LOADCELL | LOADCELL | X | X |

| HEATING SYSTEM | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| CONTROL SYSTEM | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| CHEMICAL ADDITIVES | DOP

LATEX FLUXOIL |

DOP

LATEX FLUXOIL |

DOP

LATEX FLUXOIL |

DOP

LATEX FLUXOIL |

DOP

LATEX FLUXOIL |

X | X |

| HEAT EXCHANGERS | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| – | |||||||

| TOTAL POWER (KW) | 41 | 45 | 61 | 90 | 105 | 30 | 5 |

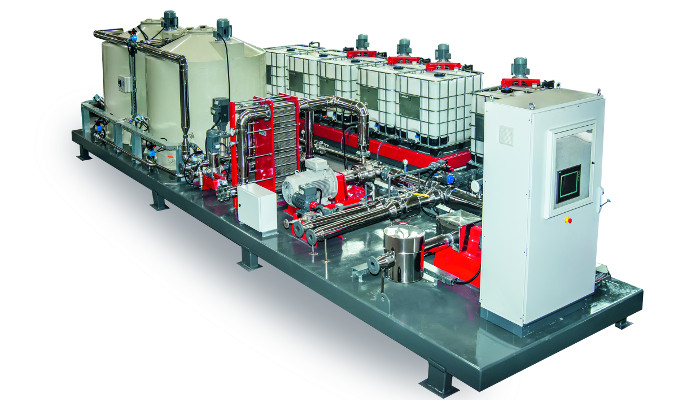

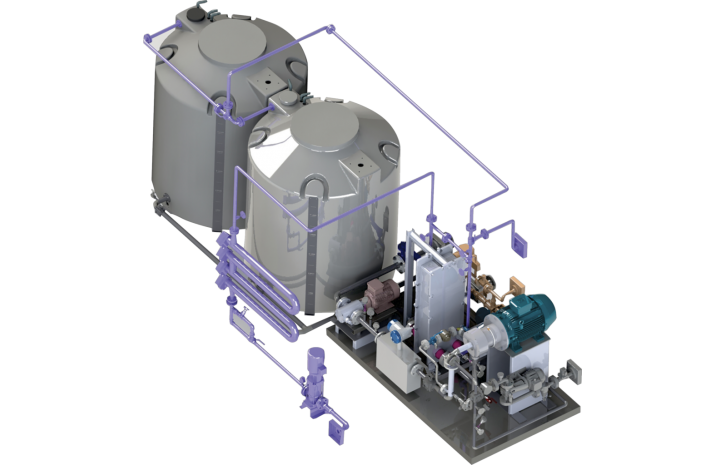

EMTES 3 Bitumen Emulsions Production

EMTES 5 Bitumen Emulsions Production

EMTES 5 Bitumen Emulsions Production

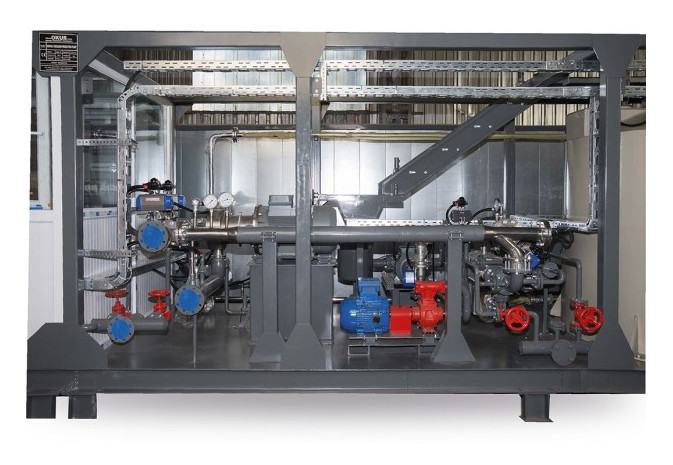

EMTES 12 Bitumen Emulsions Production

EMTES 20 Bitumen Emulsions Production

CBTES 30 Cutback Bitumen Emulsions Production

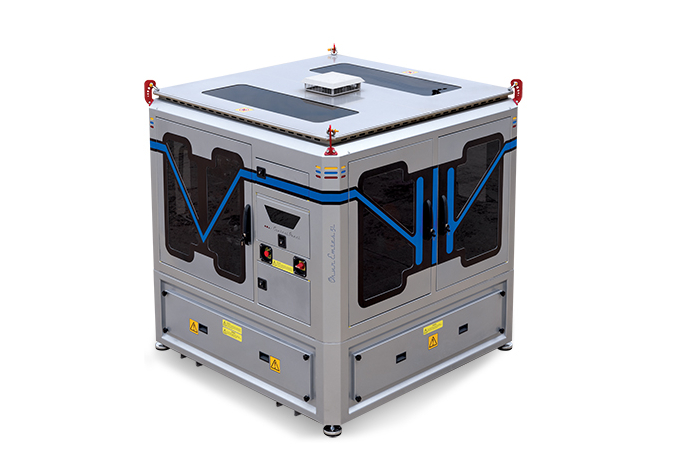

LABTES Bitumen Emulsions Production