1- The designs which are made depending on the type and quantity of application, are manufactured to be in compliance with the truck, chosen by the Customer. During road construction, a sub-base is constructed by using cement, etc. depending on the recipe at hand. Our product prepares cold mixes for sub-base also for such constructions as ports, railroads, dams, etc.

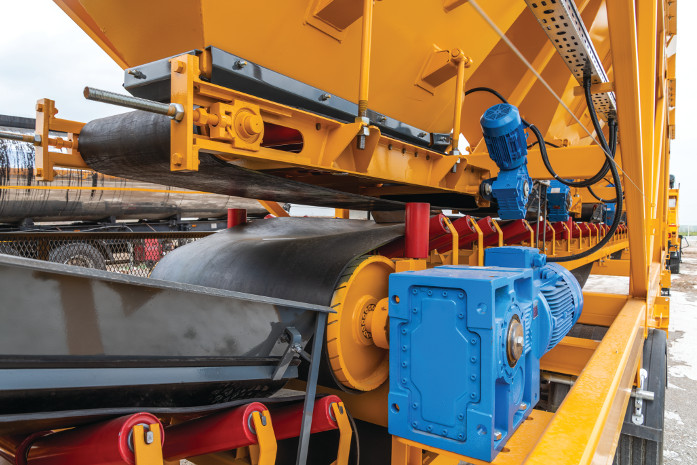

2- Thanks to advanced sensor technology different sized aggregates, water and cement, etc. which are used as binder, can be accurately dosed in order to obtain a quality and stable cold mix.

3- Our mechanical stabilization material plant, in addition to its ease of setup, transportation and operation thanks to their mobile and stationary models, can be fully functional with single operator and single button approach, employing the state-of-the-art technology.

4- Under no circumstances we compromise product’s standards for the sake of sustainable quality.

For the purpose of assuring stability and accuracy of the moisture content of the mix, water is dosed using magnetic flow meters and flow rate setting valve.

5- The machine is ergonomic and quick and practical to transport, set up and deploy. It is possible to increase variety of the cold silos, based on the customer’s requirements.

6- Thanks to its high and quick ROI (return-on-investment), its investment and operating costs are minimized.

7- Plant’s safety and security are ensured in conformity with international operating rules. It has zero CO2 emission.

8- Product quality is maintained for the sake of sustainability. Each production lot is checked for quality and and quality control results are verified by a lab technician.

9- Through modern infrastructure instruments the data is processed correctly and accurately reported and stored.

10- The system is always under control thanks to real time data transfer and remote monitoring capability.

11- We provide after-sale services at any point in the world to the same standards and without interruption.

12- The training is provided to the top management, quality control and maintenance personnel and operators, depending on their needs.

Our plant is a sought-after product which is capable of sub-base cold mixes with excellent results, needed by any type of road, railroad, damn and port infrastructure constructions.

Accuracy of the volumetric and mass measurements implemented in dosing of the materials in the cold mix silos, have direct impact on the resultant product obtained. The cement used is measured by means of a load cell and moistening water by means of a magnetic flow meter.

The fact that ratios of aggregate, cement and water are automatically controlled by means of PID, makes the product stable and operator input unnecessary.

A homogeneous and stable product is obtained thanks to bespoke mixer. Thanks to wear plates which are made of ni-hard alloys, the product is superior with respect to abrasive materials such as basal, granite, etc.

Our product is superior to its rivals with its quick deployment ability and low operating costs in comparison with the production capacity.

The plant is operated by only a single operator.

| MODELS | |||||

| OKUR MSP 200 MOBILE | OKUR MSP 400 MOBILE | OKUR MSP 600 MOBILE | OKUR MSP 400 FIXED | OKUR CMP 600 FIXED | |

| CAPACITY ( T/h) | 200-300 | 400-500 | 600-750 | 400-500 | 600-750 |

| CONTINUOUS PRODUCTION | ✓ | ✓ | ✓ | ✓ | ✓ |

| PORTABILITY | MOBILE | MOBILE | MOBILE | FIXED | FIXED |

| MIXER MOTOR POWER | 37kW x 1 | 37kW x 2 | 45kW x 2 | 37kW x 2 | 45kW x 2 |

| NUMBER OF COLD SILO | 3 | 4 | 4 | 4 | 5 |

| AGGREGATE DOSING BAND CAPACITY | 125 t/h | 150 t/h | 175 t/h | 150 t/h | 175 t/h |

| AGGREGATE DOSING BAND MEASUREMENT | Volumetric | Volumetric | Volumetric | Volumetric | Volumetric |

| AGGREGATE BELT SCALE * | Mass | Mass | Mass | Mass | Mass |

| CEMENT SILO CAPACITY | 30 T | 50 T | 50 T | 50 T | 50 T |

| CEMENT DOSING | Mass | Mass | Mass | Mass | Mass |

| WATER PUMP CAPACITY | 15 t/h | 30 t/h | 45 t/h | 30 t/h | 45 t/h |

| WATER DOSING | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER | MAGNETIC FLOWMETER |

| TOTAL POWER | 79 kW | 112 kW | 149 kW | 121 kW | 155 kW |

* OPTIONAL

Mechanical Stabilization Mobile

Mechanical Stabilization Stationary